22 Full PDFs related to this paper. This is the process by which materialsdevice safety is tested prior to animal testing.

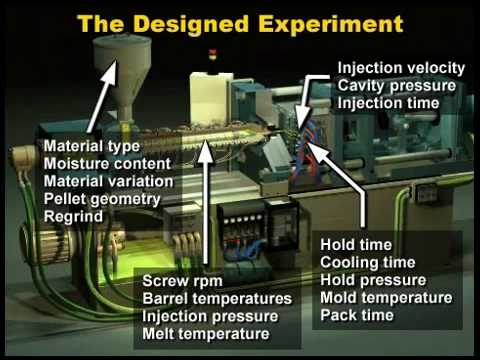

Design Of Experiements For Injection Molding Paulson Youtube

Cancer zone inner mesh.

. 21 Installation qualification IQ. Full PDF Package Download Full PDF Package. Biocompatibility testing may involve animal testing ie.

Simscape Fluids formerly SimHydraulics provides component libraries for modeling and simulating fluid systemsIt includes models of hydraulic pumps valves actuators pipelines and heat exchangers. Academiaedu is a platform for academics to share research papers. They carried out a series of experiments with piglets such as the implantation of microporous Teflon conduits as substitutes for the portal vein the inferior vena cava the external iliac vein and obtained a permeability rate equal to 80 2 months after implantation taking into account the.

Injection Molding Medical Manufacturing Tooling REQUEST A QUOTE. In two-step molding two separate machines are used. 1 Injection molding involves squirting hot plastic into a mold.

2 Definitions For this document the following definitions apply. Exposing an animal to materials or. Broken or ground samples despite being permanently cross-linked well beyond the gel point can be reprocessed by injection molding.

By adapting the mold temperature and dwell time molding without shrinkage can be achieved. 3D-MMP design for tumor-vasculature coculture model and fluorescence imaging of tumor spheroid on capillary bed. The gradual Arrhenius-like variation of viscosity enables manufacturing techniques usually limited to a few inorganic glasses.

Output and design validation is included in the GHTF document covering design control. The plastic grains light blue are passed over an auger Archimedes screw and heated to make molten plastic which can then be squirted through a needle injected into a mold. Milling can be also called as a perfect way of making tooling for die casting and injection molding.

All the complex structures are net-shape-formed. The candidate must be able to connect consumer insights technology socio-cultural and market trends in meaningful ways to uniquely solve design challenges. MIM combines the merits of powder metallurgy and plastic injection molding and offers design freedom in shape complexity and is suited for.

Terms other than those defined herein may be found in the literature. This was done to know the number of times the experiments would be run using L9 orthogonal array of Taguchis approach to design of experiment. Take channels holes curves and corners for some examples.

The body of the tube is significantly thicker as it will be inflated into its final shape in the second step using stretch blow molding. Injection molding of PET containing 35. There are other examples of titanium wearable parts made by MIM.

Sintered to a high density the watch frame weighs 6 g and has a curved surface and internal complex structures. 2 Blow molding is similar but air yellow arrow is blown into the plastic afterward to make it expand and fill the mold. The first machine injection molds the preform which resembles a test tube with the bottle-cap threads already molded into place.

A short summary of this paper. He tried with his team to extend its applications. Establishing by objective evidence that all key aspects of the process equipment and ancillary system installation.

A good base knowledge in key manufacturing processes is recommended blow molding injection molding etc. The advantage of multi-axis milling machines realizes versatile accurate and repeatable CNC milling process for production of different features and complex geometries. You can use these components to develop fluid power systems such as front-loader power steering and landing gear actuation systems.

Download Full PDF Package. A Detailed design and patterning procedure of 3D-MMP. Materials Engineering Science Processing and Designpdf.

Which translates to within the glass refers to test-tube experiments which occur in a laboratory.

Experimental Based Optimization Of Injection Molding Process Parameters For Short Product Cycle Time

Sketch Of The Injection Mould Used For The Experiments Download Scientific Diagram

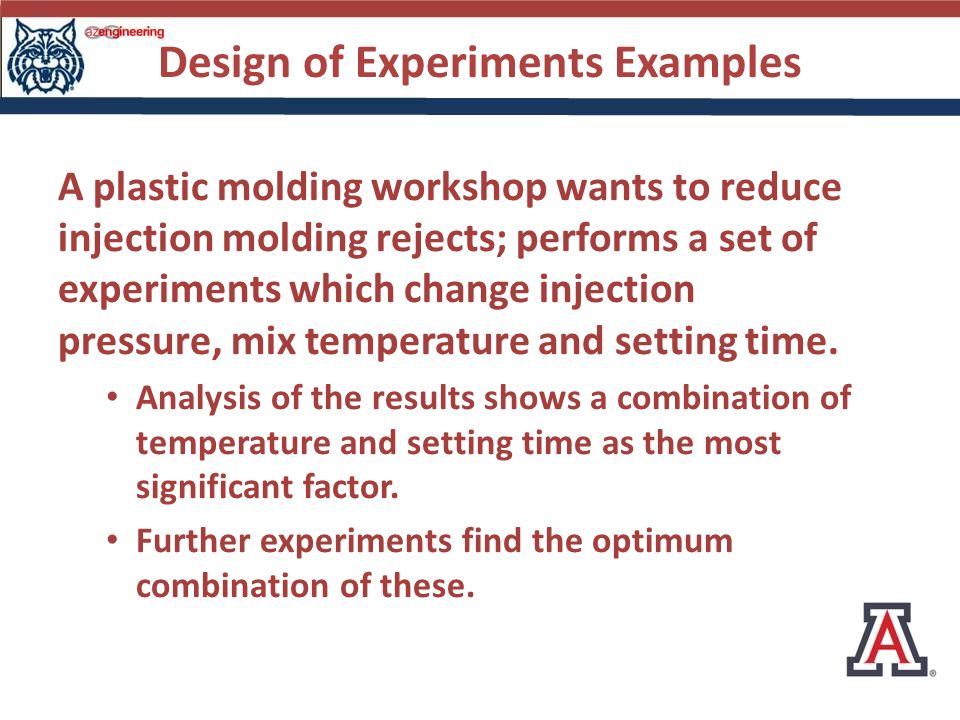

Introduction To Design Of Experiments Ppt Download

Optimal Design Parameters For Molded Injection Parts Using Moldex3d Doe On Demand Webinar Moldex3d Plastic Injection Molding Simulation Software

Design Of Experiments Doe For Injection Molding Youtube

Nautilus 8 Mold Validation And Doe Software

Optimization Technology For Plastic Injection Molding Through Design Of Experiment Doe Method Blog Moldex3d Plastic Injection Molding Simulation Software

0 comments

Post a Comment